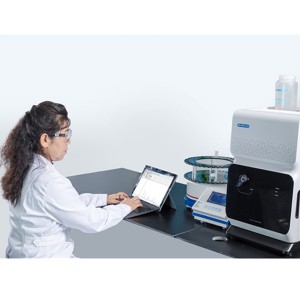

CIC-D120+ Third Generation Basic Intelligent Ion Chromatograph

Highlights

(1) It has the functions of pressure alarm, liquid leakage alarm and eluent alarm to protect the safe operation of the instrument in real time, alarm and shut down when liquid leakage occurs.

(2) The key components of the suppressor and column have real-time monitoring function to ensure the timely replacement of consumables and ensure the stability and accuracy of the instrument operation.

(3) The gas-liquid separator can effectively remove the influence of bubbles on the test.

(4) Standard equipped with SHINE high-performance autosampler, more accurate injection control.

(5) The instrument can be started up in advance according to the setting, and the operator can test directly at the unit.

(6) The software has the baseline deduction function and filtering algorithm to effectively remove the baseline drift caused by gradient elution, and the sample response is more obvious.

(7) Auto-range conductivity detector, ppb-ppm concentration range signal is directly expanded, without adjusting the range.

Application

CIC-D120+ ion Chromatograph not only provides users with a complete solution of conventional inorganic ions and disinfection by-products and additives, bromate, organic acids, amines in food, but also has complete application support in many other fields. Full plastic flow path system, widely practical application supporting scheme, with the instrument automatic injection system, so that CIC-D120+ ion Chromatograph not only has a wide range of, perfect, advanced application solution ability, at the same time to bring users automatic, humanized and interesting instrument application experience.

The chromatograph flow path system

Ultra-pure water first through the gas-liquid separator off gas into the pump, delivered by the pump into the autosampler six-way valve, when loaded into the sample loop, The sample injection valve is switched to the analysis state, and the sample in the loop enters the flow path, detergent and sample mixed solution into the guard column,analytical column, after column separation into the suppressor, conductivity detector, conductivity pool will analyze the sample, electrical signal converted into digital signal sent to the computer end for analysis. After the liquid goes out of the conductivity cell, it will enter the suppressor to supplement the water in the regeneration channel of the suppressor, and finally the waste liquid will enter the waste liquid bottle.